Entering June, it is the 23rd "Safety Production Month" in China. In order to deeply implement the series of decisions and important instructions of governments at all levels, emergency departments, and group leaders on strengthening safety production work, further increase safety production education, and create a good safety production atmosphere, Jiheng Group Blue Sky Sairui Company has launched the "Safety Production Month" theme activity and the company's second "Hundred Day Safety Competition" activity, aiming to continuously enhance the safety awareness of all employees, improve the level of enterprise safety management, and prevent the occurrence of various safety accidents.

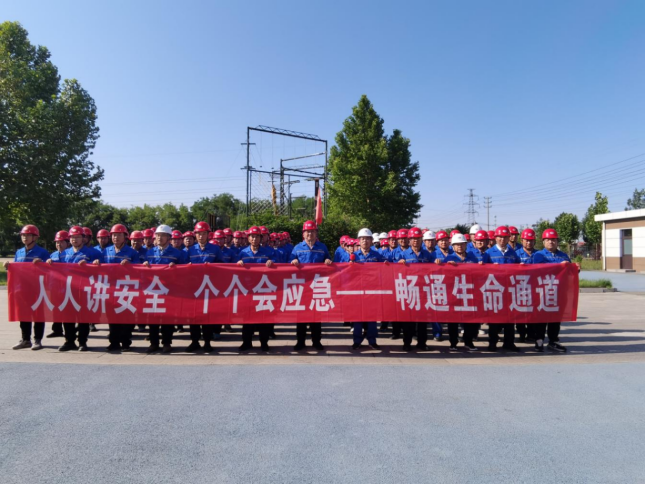

On June 1st at 7:35, the company held a grand "Safety Production Month" and the second "Hundred Day Safety Competition" event kickoff meeting. More than 130 members of the company's leadership team, functional department and workshop management personnel, as well as the entire operation team of the day, attended the conference and jointly took a safety oath.

The safety department announced the "Safety Production Month" activity plan and the "Hundred Day Safety Competition" activity plan. This year's Safety Month, the company will carry out comprehensive inspections and rectification in accordance with the requirements of the "Three Year Action Plan for Root Cause Crackdown" and the "2024 Action Plan for Special Investigation and Rectification of Major Accident Hazards in the Chemical Industry" in Hebei Province and Hengshui City, combined with the latest revised standards for determining major accident hazards in the hazardous chemical industry and the company's list of three violations. Various problems and hidden dangers will be eliminated, and the existing hidden dangers will be rectified in place and the incremental hidden dangers will be dynamically cleared. At the same time, the "construction of enterprise safety culture" will be concretized, and the impact will be amplified through various forms such as warning education, new regulations learning, safety essay solicitation, emergency drills, knowledge Q&A, and short video competitions, striving to create a standardized, orderly, safe, civilized, and innovative safety production environment.

Mr. Li of the company pointed out that the "Safety Production Month" and the second "Hundred Day Safety Competition" activities are important components of the company's strong efforts to carry out safety culture construction this year. We need to combine these two activities with the current special action of "catching three violations and preventing accidents", as well as the three-year action of tackling the root cause, and the special study of the "Hebei Province Safety Production Regulations", to effectively achieve the "three improvements", "three nots", and "one in place", so that all levels of management and employees can truly integrate the sixteen character policy of "walking on thin ice, sitting on needles, like a thorn in the back, like facing the abyss" into their minds, hearts, ears, bone marrow, and blood, truly achieving "knowing". "Unity of action" (the unity of "safety awareness", "safety knowledge and skills", and "safety behavior"), relying on the digital construction of dual prevention mechanisms, Continuously consolidating the foundation of enterprise safety, safeguarding the high-quality development of the company and the "billion yuan balance" business. (Note: "Three improvements" refer to the further improvement of employees' self safety awareness, the further improvement of safety skills of job personnel, and the further improvement of workshop self safety management level; "Three no's" refer to the absence of any accidents, major hazards, and no errors in safety inspection; "One in place" refers to the implementation of safety management work in place.).

After the kick-off meeting, the company's leaders and cadres and employees held a safety meeting with the theme of "Everyone talks about safety, everyone knows emergency - unobstructed access to life".

中文版

中文版 English

English